Sorting nuts

Optical Sorting of Nuts

Nuts are not only a tasty and healthy product, but also an essential component of the food industry. They are used to produce snacks, confectionery, vegetable oils and many other products. To ensure high quality of nuts, it is necessary to thoroughly clean, sort and process them. Modern equipment allows you to automate this process, making it fast, clear and efficient. In this article, we will consider in detail the automatic sorting of peanuts, and also touch on the features of processing other types of nuts, such as pine nuts, almonds, cashews, hazelnuts, hazelnuts and pecans.

Sorting Peanuts

Peanuts, or groundnuts, are one of the most popular types of nuts in the world. They are widely used in the production of snacks, vegetable oils, peanut butter and other products. To ensure high quality of peanuts, it is necessary to sort them thoroughly.

Imex offers photo separator for cleaning nuts, this process includes several stages:

1. Preliminary cleaning of peanuts

Before sorting, peanuts undergo preliminary cleaning from dirt, stones, stems and other foreign inclusions. For this, special sieves, air separators and magnetic systems are used.

2. Sorting peanuts by size

Peanuts are sorted by size using calibration sieves or optical systems. This allows the nuts to be divided into categories suitable for different purposes: small peanuts - for butter or paste, medium - for snacks, large - for sale whole.

3. Sorting by quality

At this stage, nuts with defects are selected: damaged, spoiled or irregularly shaped. For this, optical scanners are used that analyze each nut by color, shape and the presence of defects.

4. Separating the shell

If the peanuts are sold peeled, the shell must be removed.

5. Packaging

Sorted peanuts are packed in bags, boxes or other containers for further storage or sale.

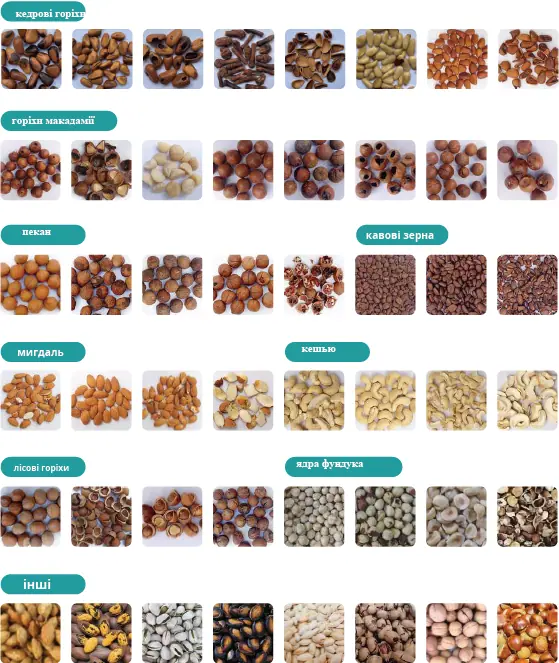

Features of sorting other types of nuts

Sorting pine nuts

Pine nuts are small kernels that require special attention when sorting. The main stages:

- Separation from cones.

- Cleaning from scales.

- Sorting by size and quality using optical systems.

Sorting almonds

Almonds are sorted by size, shape and color. Particular attention is paid to removing damaged or spoiled kernels. Calibration machines and optical scanners are used for this purpose.

Cashew sorting

Cash is sorted after preliminary heat treatment. Main stages:

- Shell separation.

- Sorting by size and quality.

- Removal of defective kernels.

Imex offers to sort pine nuts, almonds, cashews using a photoseparator with artificial intelligence.

Hazelnut sorting

Hazelnuts are sorted by size, shape and quality. Particular attention is paid to the removal of empty or damaged kernels. Calibration sieves and optical systems are used. then you can process the hazelnuts.

The Imex website offers buying a photoseparator for sorting hazelnuts with AI (artificial intelligence).

Pecan sorting

Pecans are sorted by size and quality. After sorting, the nuts are often peeled for sale in peeled form.

Nut sorting is an important stage that ensures high product quality and increases production efficiency. Modern equipment allows you to automate this process, making it fast, accurate and cost-effective. If you are looking for a reliable solution for sorting nuts or coffee beans, contact Imex Group - Photoseparator with deep learning AI will become your reliable partner in achieving success!