Taiho palletizing robot and automated logistics systems

Hefei Taihe Optoelectronics Technology LTD. has developed and introduced a new generation of palletizing equipment, which is characterized by its reliability and innovation. Taiho palletizing robot integrates multidisciplinary advanced technologies in the fields of mechanical engineering, electronics, automation, control and artificial intelligence to meet the high-speed and high-efficiency palletizing requirements. Taiho robots are better, faster, more advanced and exceed customer expectations.

Palletizer

Taiho palletizers are automated systems designed to stack various types of products on pallets. They are often used on production lines and in warehouses to speed up and optimize the packaging and transportation processes. Taiho palletizing robots for production are known for their reliability, high speed and accuracy, as well as versatility. Their lineup includes compact models for small businesses, as well as powerful units capable of handling heavy loads in large volumes.

The main features of Taiho palletizers include:

- High productivity: fast and accurate palletization of products.

- Ease of operation: an intuitive interface that allows the operator to easily adjust the parameters.

- Low maintenance costs: durable components and minimal need for regular maintenance. Low noise and power consumption.

- Adaptability: the ability to adjust to different product sizes and shapes, as well as to specific packaging requirements. Convenient product gripping system.

- Ergonomic design: the robot structure is made of aluminum.

Some models are also equipped with robotic manipulators for maximum flexibility and efficiency. Often, an industrial robot manipulator is needed in production.

Taiho palletizing robots

Taiho palletizers are closely related to industrial packaging lines, as they are an important part of the automation of packaging and logistics operations. Taiho packaging lines include various stages - from forming and filling the package to sealing and labeling. Robotic palletizers add the finishing touch by stacking finished products on pallets for easy transport and storage.

Integrating robotic palletizers into packaging lines in manufacturing:

- Automate the process: Reduce manual labor and errors, increasing overall productivity.

- Efficiency:Increase the speed of palletizing and packaging products, allowing products to be brought to market faster.

- Reduce costs: Optimize warehouse space and minimize product damage.

- Flexibility: Can be quickly reconfigured to handle different packaging types and sizes.

Taiho palletizers are therefore an integral part of their packaging solutions, ensuring efficient completion of the production line. cycle.

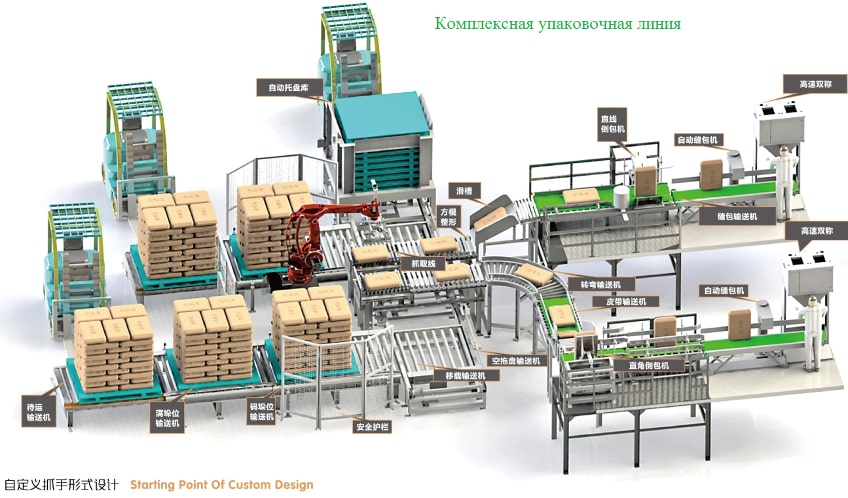

Taiho Complete Packaging Lines

Taiho packaging lines are complete automated systems designed to handle, pack and label products at various stages of the production process. These filling and packaging lines are widely used in industries such as food (including beverages), pharmaceuticals, cosmetics, grain processing, printing and many others.

Main components of Taiho packaging lines:

- Package formers: Devices that form packages (such as boxes or containers) from flat materials such as cardboard.

- Filling machines: These machines fill packages with products, whether liquids, powders or solids. They can be configured to handle a variety of different types of packaging.

- Sealing Machines: Ensure that the packaging is securely closed using adhesive tape, heat-sealable film, or other methods.

- Labeling Machines: Apply information to the packaging such as manufacturing date, expiration date, barcodes, and other necessary information.

- Palletizers: As discussed, these machines stack finished products on pallets for easy storage and transportation.

- Quality Inspection Systems: Include sensors and cameras to check the quality of the packaging to ensure guarantee compliance with standards.

Advantages of Taiho Packaging Lines:

- Automation: Reduces manual labor and increases operating speed.

- Modularity: The line can be configured to meet specific needs and product types.

- High reliability: The components and technologies used in the lines ensure durability and low maintenance costs.

- Integration with other systems: The ability to connect with other automated systems, such as transportation and storage, to create a single production flow.

Comprehensive Packaging Line

Taiho's comprehensive packaging line can be adapted to various types of bulk products, making it a versatile solution for many enterprises. This allows companies to optimize their packaging and logistics processes, as well as meet market and customer requirements.

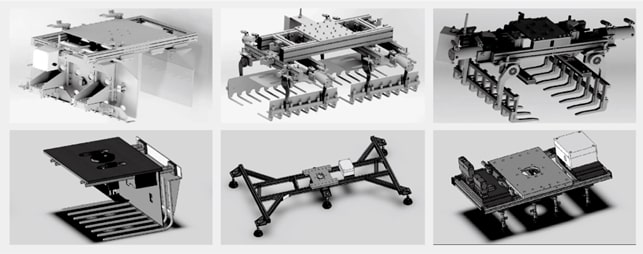

Taiho has developed and implemented new product gripping systems. They are optimized for the robot's operation for various types of packaging, making the robot more advanced and versatile for a wide range of applications.

Please note that we can offer a comprehensive packaging solution for your enterprise "turnkey" at a good price, including the supply of conveyors, packaging machines, etc. To prepare a commercial offer, please send us the technical specifications.

If you have any further questions, please contact us in any convenient way.

How to purchase a palletizer on the Imex Group Service website?

- Fill out an application on the website or call.

- Delivery time - 8 weeks.

- Partial prepayment is possible.

- Payment by bank transfer.

- Delivery throughout Ukraine.

Our company also offers comprehensive automated logistics solutions. You can see an example of how such a complex works in the video below.